software

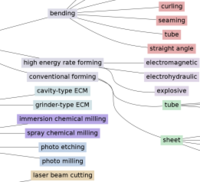

Societal Engineering Knowledge Database, a system to share designs, manufacturing processes, tools, resources, and explain how to use them in an automated fashion.

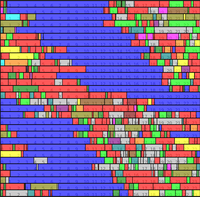

graphical representation of my "Guinea Pig C" lifelog data: blue is sleep, red internet, green food, yellow programming, etc

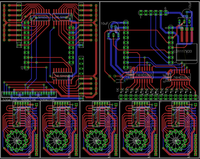

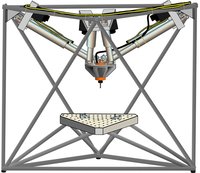

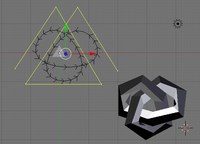

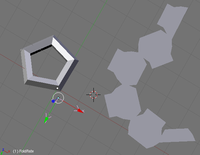

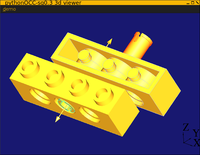

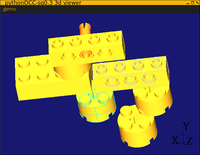

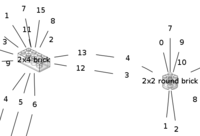

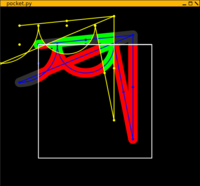

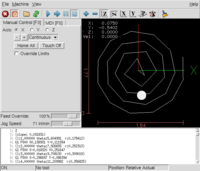

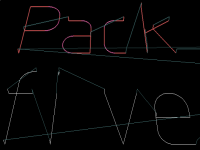

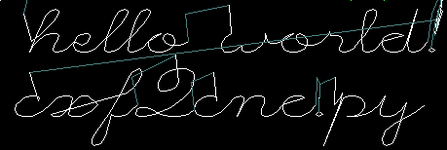

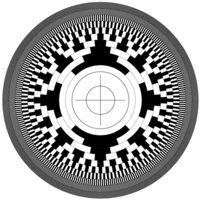

CAM algorithms - offseting polygons, a curve-length-parameterized spiral which prevents path planning queue overflow at the center, a stick font engraving program, based on the hershey fonts

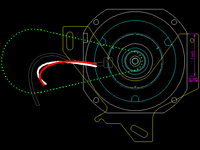

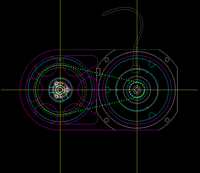

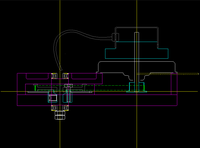

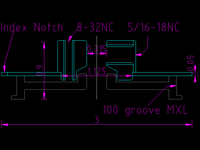

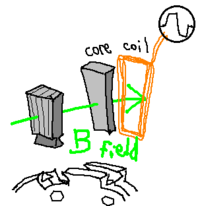

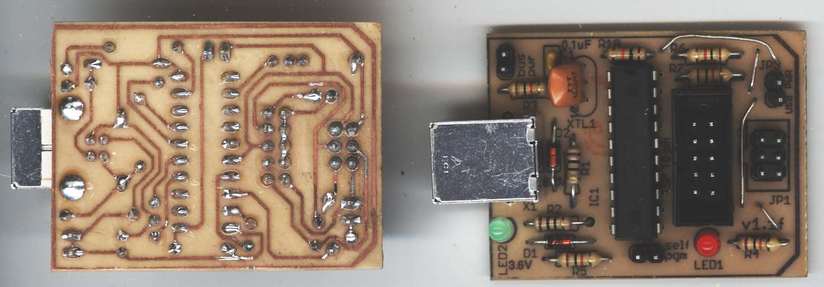

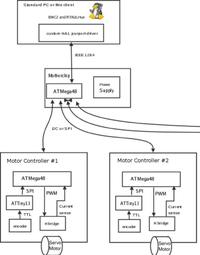

a DIY "smart servo" with PID control running on an AVR in fixed-point, and printed optical encoder wheels, for controlling the CNC lathe

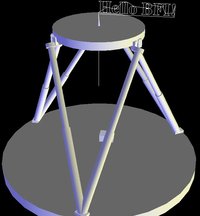

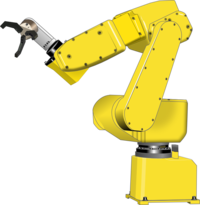

wrote the gait sequencing code for the tiptoes robot, which was a project with a friend in Australia